Introduction

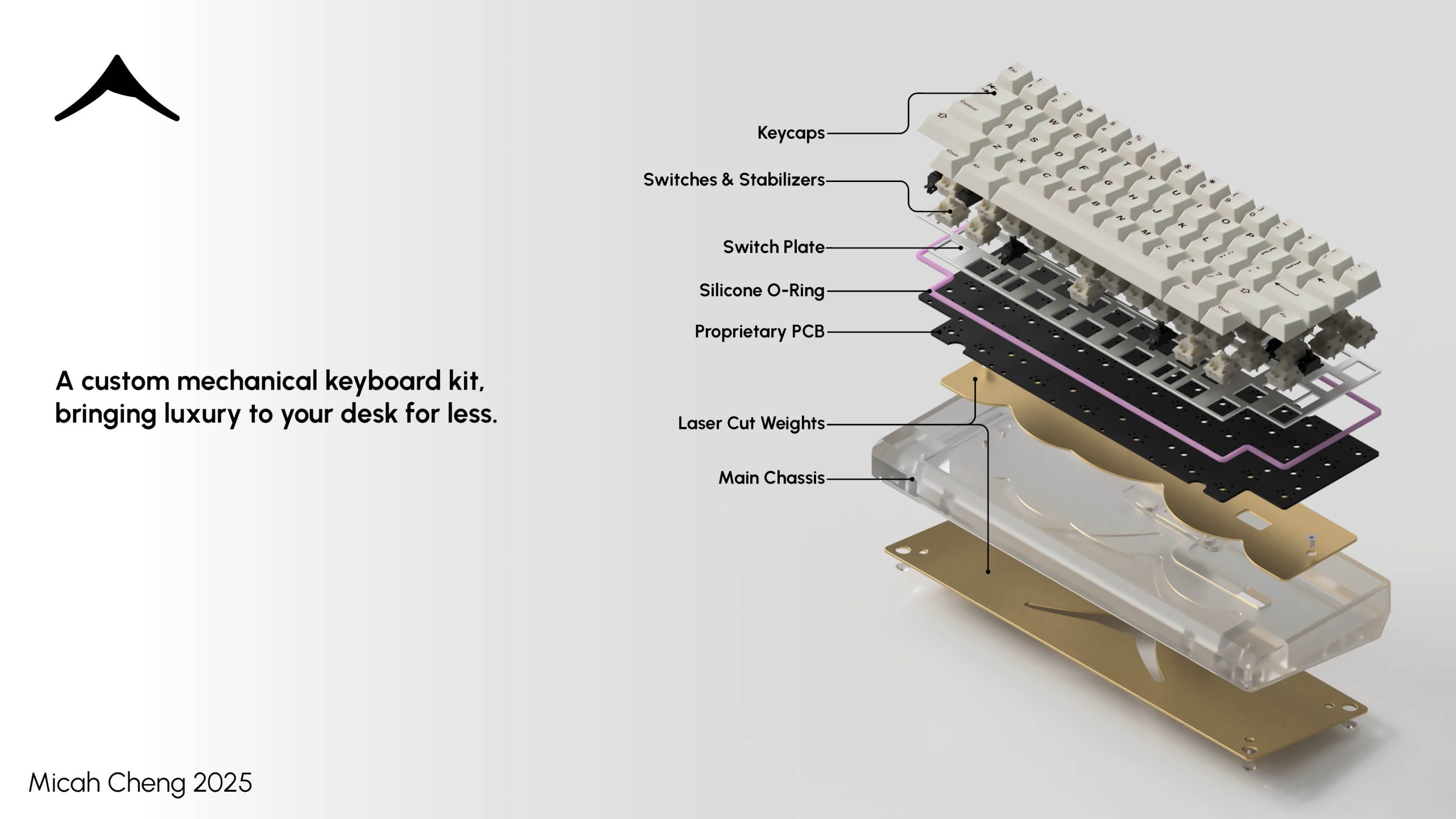

A long-term passion project of mine turned production-scale, the Summit is a custom mechanical keyboard kit designed for enthusiasts craving authentic design, from the inside out.

Features

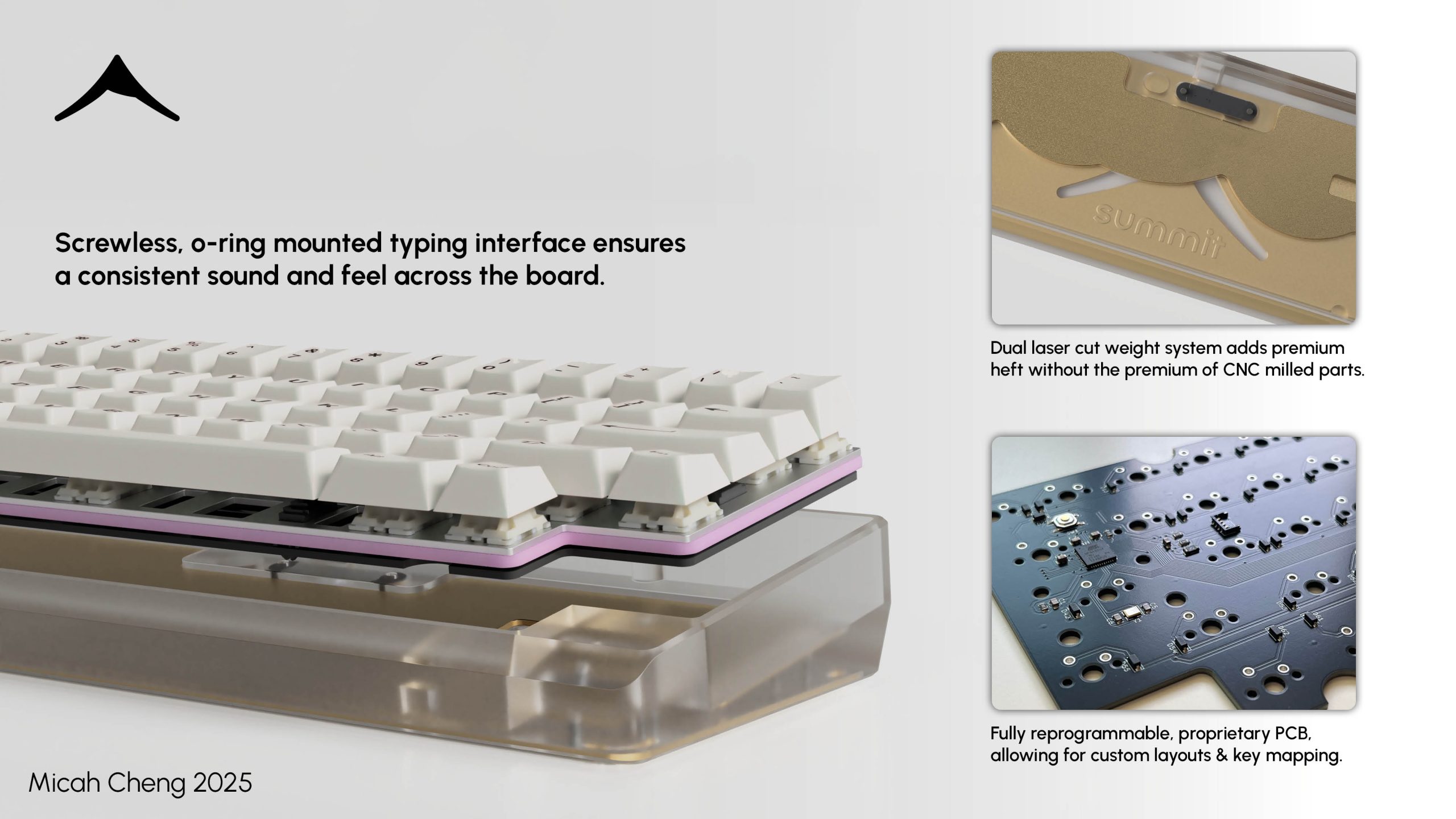

Most notably, the Summit features a Gummy O-Ring mount, a unique, screwless method of friction-fitting the typing interface into the outer chassis. This ensures a uniform sound and feel across the board, a features never achieved by traditional prebuilt mechanical keyboards that are have the typing interface mounted with hard fasteners and standoffs.

The Summit also minimizes manufacturing costs when compared to other enthusiast keyboards, through its laser-cut weight system. A must for any high-end custom mechanical keyboard is to have a significant amount of weight, as it not only keeps the keyboard more secure on the user’s desk, but also improves the acoustics due to the higher density of the chassis.

Most enthusiast-level keyboards accomplish this heftiness through the inclusion of CNC weights, made out of denser metals, such as Brass, Copper or Stainless Steel. However, as one can imagine, this can get expensive extremely quick. The Summit, rather than using extremely expensive CNC weights, features low-cost Laser Cut weights instead, greatly reducing manufacturing costs and material waste, while retaining the luxury feel of raw Brass or Stainless Steel.

Prototyping & Development

I took the Summit through several prototype phases, making improvements on the design, manufacturability, and ease of assembly with each iteration. I learned a lot through this experience, not only about the whole process of designing manufacturing-ready parts, but also about creating Bills of Materials and comparing vendors to minimize production costs.

If you’ve stuck around this far, consider checking out the YouTube video for a much more in-depth process of making the Summit!